Stick Dulcimer making course part1, tools......

Over the next few weeks I am uploading the chapter contents of the Stick Dulcimer DVD, this easily lays out the notes between the videos and allows you to search and jump to certain topics.

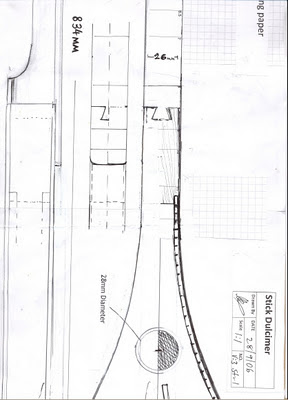

The plans are still available from my website for download as are the tailpieces and DVD's.

We begin looking at the tools you will need

Tools

There are many specialist luthier tools but for this project you

can get by with a normal tool set, Do have a look at stewmac.com

and other luthier supplies for inspiration though!!

Handtool List

Smoothing plane, bailey

pattern(record/Stanley no.4/5)

set of chisels, including 1/4,

8mm, 1"

Dovetail or small dozuki

Japanese

saw

Coping saw (if without Bandsaw)

Large or Junior

Hacksaw(can

cut angle brass/sheets )

Nordic style

whittling knife (frosts

of

Sweden,

make a good cheap one with Birch handle)

Spokeshave flat bottom

can be good for neck carving

Diamond sharpening stone, or oil/whetstone

set of scrapers

bradawl/marking awl

Marking knife(Japanese one recommended)

Marking gauge(the veritas one is my favourite,)

square(metal engineers)

1mtr ruler

assorted metal drill bits, including 1.5mm for string holes in

tailpiece, 9.5mm for peg holes(check pegs first before drilling,

use scrap to test!)

sand paper assorted grades, cloth backed ones last longest

Various sanding blocks

sanding board, made to fit whole sheet of Sand/Glass-paper for

levelling the body prior to gluing up!

Workshop/Workspace

In order for any work to be done you will need some place to work with

a stable bench/surface. When I graduated from University began I had to

just use my workmate outside and my kitchen table to work on, I

then had a couple of workshops and then a 35 foot by 12 foot shop.

I downsized in 2005 building a

7ft square shed at home, that now

somehow fits all my tools and a bench.

Building a purpose built space, however small means you can control

your environment.

My shed is insulated with 1" polystyrene and lined with mdf

boards, plus noise reduction boards under the laminate flooring.

I had the electrics installed by an electrician.

I use an oil filled heater in the winter to keep the temperature around

21%c, set very low, and Humidity is monitored with a digital

Hygrometer, so I never glue anything together if the shop isn't

between 40-50% humidity. In the summer when its too humid I use a

de-humidifier, (It only takes an hour to bring a small 7x7x7shop to

safe levels)

The brass Hygrometers are cheap to buy and fine enough to use, though

the digital ones, often sold for wine making as well as well as

Luthiery are Very accurate, and can even let you know the min/max

humidity/temperature of your working/storing environment.

I have maximized my working space in the summer by having an

outdoor woodworking bench, mainly for using hand tools, It

frees my workshop to be then used for gluing up and machining.

If you cant have a permanent space, or your workshop/space is damp or

outside, then try to have a cupboard, or a big box inside

the house for your wood to go in between working. whatever you do

try to glue up/nail together the wood when it has had some time to

adjust to the humidity.

If you are making your own bench do have a very simple pattern which

just requires a handsaw and an electric screwdriver. I have used

construction grade pine and a plywood top(two 18mm layers to make a

solid worktop. For your bench height I would recommend 3"

below your elbow as a good height to save your back, but do try

different tables/surfaces first to see what suits you.

Vice/clamp/cramps

I tend to use the Wolfcraft make of clamps as they have a reliable

mechanism and clamp really well, 2 is the minimum number, though

more is always handy. I also use lots of the all metal screw G or

C clamps. The violin clamps I use to close/glue the sound

box can be purchased from luthier supplies, but I have tended to buy

the butterfly nuts, washers and roofing bolts and make my own with cork

or old leather belts to line the inner surface..

Glue pot

Titebond is the only modern glue I would heartedly recommend for this

instrument, although for several years now I have mainly used

traditional animal glue. This is used in a small

jar placed in a second hand baby bottle/food heater(from ebay!!)

this has worked out to be an a very accurate tool to heat

the glue.

Bending Iron

On the Video I use a method involving boiling

water, this is a simple way but does require a week of drying out time

so its best for limited productions. I have an electric Bending

iron I for normal use but they are pretty expensive and you can

probably wait until you are bending a number of ribs or making guitars

until getting one!

Bench Drill

The only power tool I set as a absolute requirement is a bench or

pillar drill, with this you can accurately drill the holes for the

pegs, cut the rosette channel with forstner bits and even thickness

with a gilbert sanding disk attachment!! I even use this tool in the

video to thickness the headstock. You cannot use forstner bits

without this fixed drill tool.

using

a foam sanding attachment you can shape the bridge and the head/neck

area. You can use a drill attachment press but in my experience

these are less accurate.

A small tabletop 5-speed bench drill is fine for this project and

economical to buy.

Bandsaws

The

Bandsaw,

isn't

essential,

but just saves a lot of energy and time. It is

perfectly

possible to cut out the shape roughly by hand and clean up on the

sander, but the bandsaw does cut very accurately.

It is also good if you are recycling wood and doing lots of resawing,

cutting out the wood for the sides.

Planers/Jointers

Planers/Jointers

- I have a small benchtop planer(a

thicknesser

in

England) that I use to

get some of my wood to size, especially necks

- I don't recommend using a this to plane down figured woods

like maple, Commercial suppliers use large sanding drums to

thickness these woods.

Router

One handy tool for bindings is

the

Router,

preferably

a

good

1/2 one, though the smaller 1/4" Routers will work

fine if you make light cuts, in several stages.

For best results I would recommend you go

on a weekend router course or night classes to use one of these well,

There are also may books and DVD's you can buy to learn more.

When

working

inside

you

will need to use some sort of dust collection, plus

wear mask and goggles, I really recommend some person to person

training here! This tool for our purposes is used in combination

with a simple

router table made of 1/2" or 12mm MDF board to create an 18"

box, Or a commercially available one like I show in my video.

You could make the mould for the Stick Dulcimer of other

more costly materials, plastic and aluminium for example by taking your

MDF mould to a machinist shop where industrial routers can make your

mould for you.

The last power tool I recommend

is a good

Bench

top

Disc Sander, This will

clean up a lot of you sawmarks and help shape the top and bottom

blocks quickly,

I sometimes use them to sand the ends of the frets before filing down

and for making the bridge and tailpiece it is vital.

These machines are also pretty quiet to use, but you need to have

a strategy in place for the volume of Dust they create!! always

use

a

dust mask and dust extraction with these machines!

You could consider the combination disc and belt sander as an

alternative if you have the space!